HIGHLIGHTS

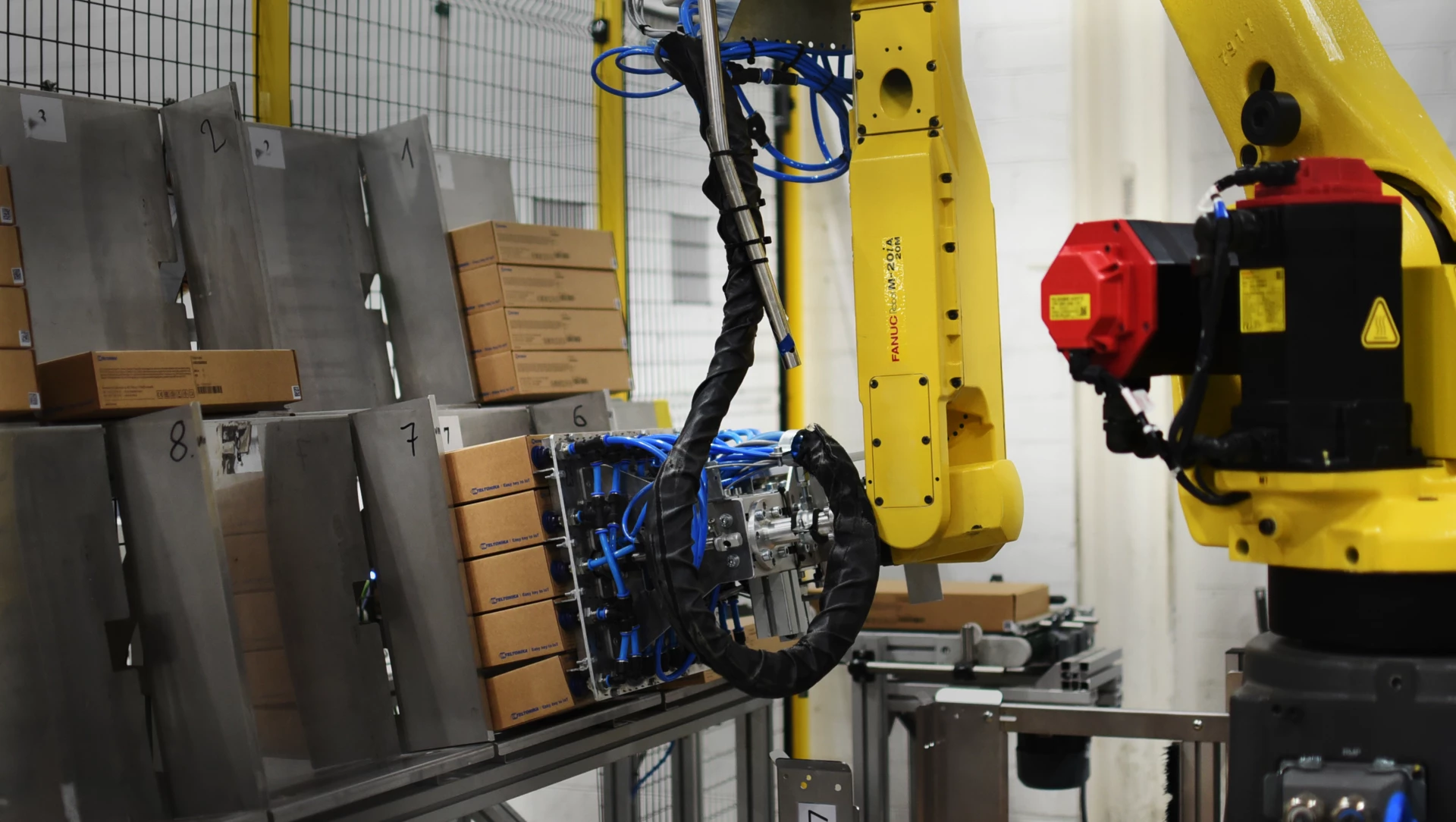

✔ In the rapidly expanding industrial sector, companies are increasingly automating manufacturing and assembly lines to enhance efficiency.

✔ The Teltonika RUTM55 5G router is a great fit for the task due to its ultra-high 5G cellular speeds, redundancy with dual SIM & eSIM, and RS232/RS485 serial interfaces, ensuring seamless integration of legacy equipment.

✔ With its robust design and remote management capabilities via Teltonika RMS, the RUTM55 eSIM router provides a future-proof solution for maintaining always-on performance and control in demanding industrial environments.

THE CHALLENGE - CONNECTING LEGACY AND NEXT-GEN INDUSTRIAL SYSTEMS

The industrial landscape is undergoing continuous growth, with manufacturing plants constantly increasing in number. In fact, the number of enterprises in the manufacturing market is expected to reach a record 5.52 million in 2024, growing to 6.14 million by 2029.

This expansion presents a significant challenge in keeping pace with technological advancements, especially when hiring and training new personnel takes time. Companies are increasingly turning to automation to boost factory efficiency, with the global Industrial IoT (IIoT) market, a key enabler of this automation, estimated to reach USD 1,693.44 billion by 2030, growing at a CAGR of 23.3% from 2025 to 2030.

However, automating manufacturing lines is often a gradual process, leading to the challenge of connecting a mix of old and new technologies. Different interfaces often require different connection types, which can escalate costs. Purchasing the latest technology doesn't guarantee that it will be compatible with existing factory setups. Many production lines feature a blend of complex and straightforward components, often relying on expensive connectivity solutions.

Furthermore, while on-site staff can typically resolve common malfunctions or software updates, more complex issues, particularly with custom-made machinery, require the expertise of the manufacturer's engineer. This can lead to significant obstacles such as distance, travel costs, and production line shutdowns during maintenance.

Unplanned downtime, a critical concern in manufacturing, costs industrial manufacturers as much as $50 billion a year. The primary challenge, therefore, lies in interconnecting all factory systems to enable centralized control for on-site monitoring and remote access for experts when required, minimizing costly disruptions and maximizing operational efficiency.

TOPOLOGY

THE SOLUTION - CONNECTED INDUSTRIAL ECOSYSTEM WITH RUTM55 5G ROUTER

In this setup, the RUTM55 5G router serves as the central connectivity hub, utilizing its robust 5G/4G capabilities—including backward compatibility with LTE Cat 19—to establish a secure connection to the Internet. Locally, the RUTM55 eSIM router's integrated Gigabit Ethernet, RS232/RS485, and I/Os enable direct and seamless integration with a comprehensive array of industrial components within the facility.

The RUTM55 mobile router leverages its ultra-high 5G cellular speeds of up to 3.4 Gbps to provide robust and fast internet connectivity for all network components. This is a critical capability for real-time data transmission from sensors, machinery, and control systems to a central control center or the cloud.

To ensure always-on performance, the RUTM55 5G router features dual SIM and eSIM capabilities, with the eSIM supporting up to 7 profiles. This provides enhanced flexibility and automatic failover, guaranteeing uninterrupted connectivity even if one cellular network experiences an outage. Such redundancy is particularly vital in manufacturing environments where even minimal downtime can lead to significant financial losses.

The RUTM55's integrated RS232 and RS485 serial interfaces are crucial, allowing legacy industrial devices to be brought online without expensive upgrades or replacements. This ensures that older machinery, such as PLCs and HMIs, which typically communicates via serial protocols, can be seamlessly integrated into the modern network.

Furthermore, the versatile digital input/output (I/O) ports accommodate other critical supporting systems; for example, a panic alert button can connect to one digital input, and an RFID reader can utilize another. This extensive interface suite facilitates vital data exchange across all operational elements. This comprehensive connectivity supports everything from automated process control and human-machine interaction to environmental monitoring and critical safety functions.

All data from these connected devices is securely routed through the RUTM55's 5G connection to the Control Center. Besides, all the connected devices can also be remotely reached by the Teltonika‘s Remote Management System (RMS) This allows for centralized monitoring and management, providing authorized personnel, including external experts, with full remote access.

Through RMS, users can efficiently troubleshoot issues, deploy firmware updates, adjust device configurations, and collect real-time and historical data from anywhere with internet access. This remote capability drastically reduces the need for on-site visits, cutting down travel costs, minimizing production line shutdowns, and enabling swift and efficient expert intervention.

Ready to enhance your manufacturing operations with cutting-edge 5G connectivity and seamless remote management? Contact us today and find the best option for your needs.

Featured product

RUTM55Ultra-high cellular speeds of up to 3.4 Gbps

Ethernet, Serial (RS232, RS485) and multiple Inputs/Outputs

Redundancy & reliability via auto-failover

Tailored for industrial use